Arc-shaped and special-shaped designs endow lighting and home furnishings with a stronger sense of art. However, aluminum alloy profiles commonly used by lighting enterprises often encounter problems such as uneven surfaces, cracks, and wrinkles during bending processing. Minor issues directly affect the appearance of lighting fixtures, while more serious ones can also impact the performance and service life of lamps.

The new generation of variable curvature CNC roll bending machine independently developed by G Clef does not require the replacement of toolings according to different radii. It can achieve the bending of profiles with different curvatures, and there is a smooth transition between arcs. It perfectly solves processing quality problems such as poor surface finish, cracks, and wrinkles of profiles. It can also ensure product consistency, effectively improve production efficiency and reduce labor costs.

Core Competence

Continuous roll bending

For contours such as von Kármán curves, ellipses, S-curves, and equidistant spirals, they can be completed by one or multiple repeated bends.

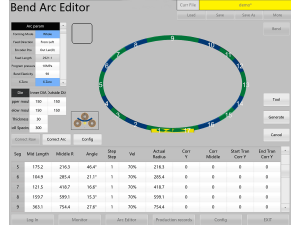

Digitalized and graphical production

Import CAD or STP to directly generate relevant parameters such as tooling diagrams, programs, and shaft distance without relying on human experience.

Stable production

The equipment has stable performance. The repeat positioning accuracy can reach 0.01mm, ensuring product consistency.

Leave A Comment