-

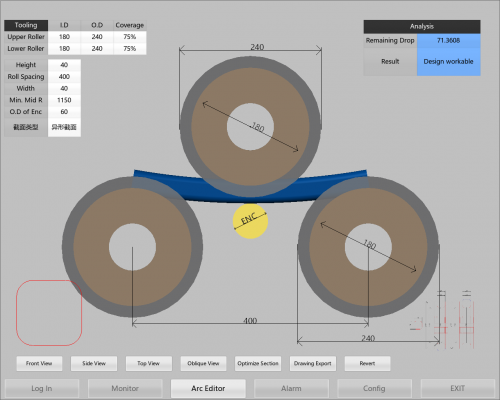

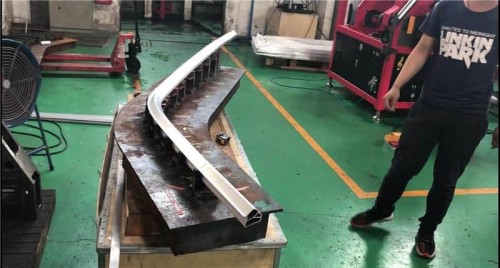

Vertical roll bending machine A12T can bend multi-radius arcs, ellipses, parabolas and other curvatures. 2D or 3D bending function is available. The 4th roller can be customized based on your needs. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. As our mature product, the sample-making period and lead time are short to satisfy your urgent needs. Profile max cross-section area: 60*60*3mm. Min. bending radius: section height* 5-8.

Vertical roll bending machine A12T can bend multi-radius arcs, ellipses, parabolas and other curvatures. 2D or 3D bending function is available. The 4th roller can be customized based on your needs. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. As our mature product, the sample-making period and lead time are short to satisfy your urgent needs. Profile max cross-section area: 60*60*3mm. Min. bending radius: section height* 5-8. -

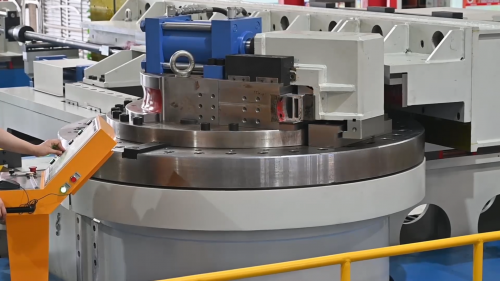

G-Clef vertical CNC roll bending machine A20T is widely used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, gym equipment and other industries. 2D /3D bending is optional. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. Profile max cross-section area: 100*100*3mm. Min. bending radius: section height* 5-8.

G-Clef vertical CNC roll bending machine A20T is widely used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, gym equipment and other industries. 2D /3D bending is optional. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. Profile max cross-section area: 100*100*3mm. Min. bending radius: section height* 5-8. -

G-Clef vertical CNC roll bending machine A30T is widely used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, gym equipment and other industries. 2D /3D bending is optional. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. Profile max cross-section area: 100*100*3mm. Min. bending radius: section height* 5-8.

G-Clef vertical CNC roll bending machine A30T is widely used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, gym equipment and other industries. 2D /3D bending is optional. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. Profile max cross-section area: 100*100*3mm. Min. bending radius: section height* 5-8. -

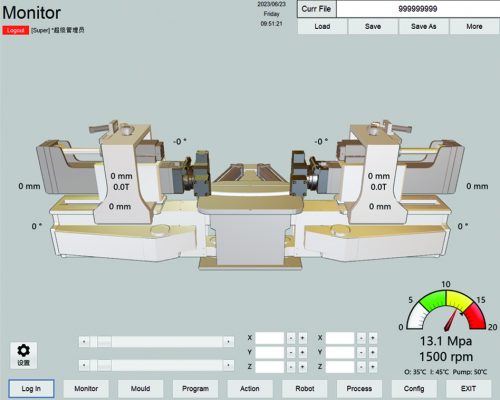

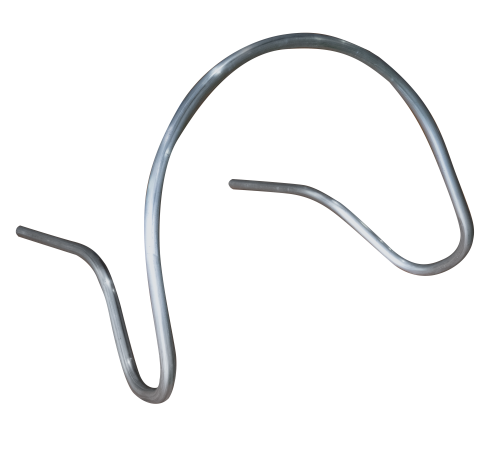

G Clef Roll Bending Machine G-CNC-S10T is able to bend tubes and profiles in both directions of LH/RH, which can satisfy your needs of complex-shape bending. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost.

G Clef Roll Bending Machine G-CNC-S10T is able to bend tubes and profiles in both directions of LH/RH, which can satisfy your needs of complex-shape bending. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. -

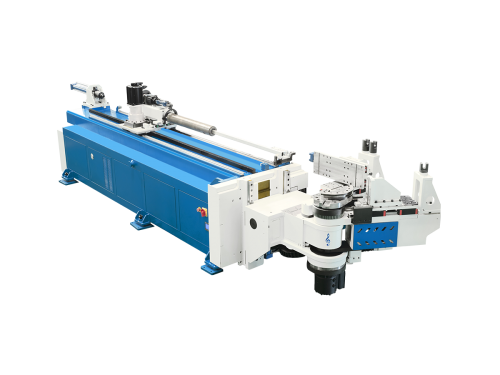

This machine A210D can bend 210×12mm steel pipe, suitable for medical equipment and other industries. Equipped with a CNC system, G Clef tube bending machine has bending capabilities of multi-radius, multi-angle, and multi-direction. Adopting original eccentric bending technology, it can realize small radius bending. Moreover, there is no need of manual correction after bending. It can be adapted to a wide range of machines (robot grippers, drilling devices, etc.), and realize automated production.

This machine A210D can bend 210×12mm steel pipe, suitable for medical equipment and other industries. Equipped with a CNC system, G Clef tube bending machine has bending capabilities of multi-radius, multi-angle, and multi-direction. Adopting original eccentric bending technology, it can realize small radius bending. Moreover, there is no need of manual correction after bending. It can be adapted to a wide range of machines (robot grippers, drilling devices, etc.), and realize automated production. -

Equipped with a CNC system, G Clef tube bending machine has the bending capabilities of multi-radius, multi-angle, and multi-direction. Adopting original eccentric bending technology, it can realize small radius bending. Moreover, there is no need of manual correction after bending. It can be adapted to a wide range of machines (robot grippers, drilling devices, etc.), and realize automated production.

Equipped with a CNC system, G Clef tube bending machine has the bending capabilities of multi-radius, multi-angle, and multi-direction. Adopting original eccentric bending technology, it can realize small radius bending. Moreover, there is no need of manual correction after bending. It can be adapted to a wide range of machines (robot grippers, drilling devices, etc.), and realize automated production.