Stretch forming is a metal forming process in which a piece of sheet metal is stretched and bent simultaneously over a die in order to form large contoured parts. Stretch forming is performed on a stretch press, in which a piece of sheet metal is securely gripped along its edges by gripping jaws. The gripping jaws are each attached to a carriage that is pulled by pneumatic or hydraulic force to stretch the sheet. The tooling used in this process is a stretch form block, called a form die, which is a solid contoured piece against which the sheet metal will be pressed. The most common stretch presses are oriented vertically, in which the form die rests on a press table that can be raised into the sheet by a hydraulic ram. As the form die is driven into the sheet, which is gripped tightly at its edges, the tensile forces increase and the sheet plastically deforms into a new shape. Horizontal stretch presses mount the form die sideways on a stationary press table, while the gripping jaws pull the sheet horizontally around the form die.

Stretch Form Capabilities

We have the ability to form aluminum alloys, stainless steel, titanium, inconel within the limitations of machinery and material properties. We stretch form sheet skins as well as extruded, roll formed, and press brake shapes.

Stretch forming equipment produces complex shapes by stretching a metal sheet, plate or extrusion over a form die. Stretch formed parts provide better shape control and surface quality than rolled or drawn parts. The stretch forming process subjects a metal blank to both plastic and elastic deformation. First, the blank is positioned on a die table and locked into place with hydraulic holding jaws. A ram-driven punch then stretches the material over the die to produce the desired shape. When the workpiece is unloaded, the plastic component of deformation is retained. Some stretch forming equipment is used to produce aluminum parts for the automobile industry or titanium parts for aerospace applications. Stretch formed parts are also used in household appliances and various sheet metal applications.

There are two basic types of stretch forming equipment: longitudinal and transverse. Longitudinal equipment stretches the workpiece along its length. Transverse equipment stretches the workpiece along its width. For both types of stretch formers, specifications describe the jaws, die table, and hydraulic system. Jaw specifications include: number of jaws, jaw width, distance between jaws, stroke per jaw, tonnage per jaw, jaw swing, and gripping pressure. Die table specifications include: size and weight, minimum and maximum tonnage, workpiece length and width, tilt angle, forming speed, and stroke. The hydraulic system for stretch forming equipment has two main parts: the power unit and the ram. Motor speed, pressure, flow, and fluid type are important power unit parameters. Force, stroke, open/close rate and pressing rate describe the ram. Hydraulic system specifications also include minimum and maximum tension cylinder pull. With some stretch forming equipment, each arm is operated by its own cylinder.

Stretch forming equipment can be interfaced to a host computer and may include features such as computer numeric control (CNC) and an integral front panel or console. With CNC machines, an operator can program the radius of the jaw instead of manually adjusting the locking screws on the curving arm for each jaw assembly. Software for stretch forming equipment is also available.

Related products:

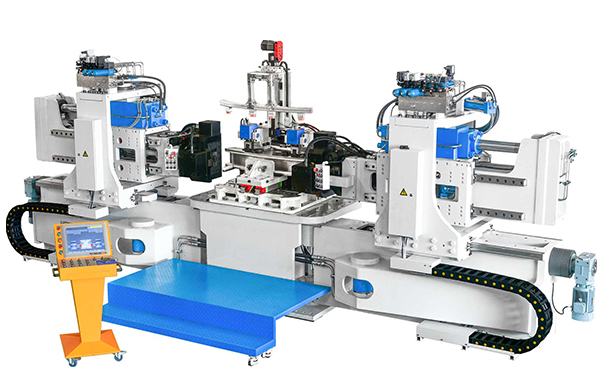

Car Bumper Stretch Froming Machine

Click here get more bending machine information onYouTube

Leave A Comment