Innovation never stops

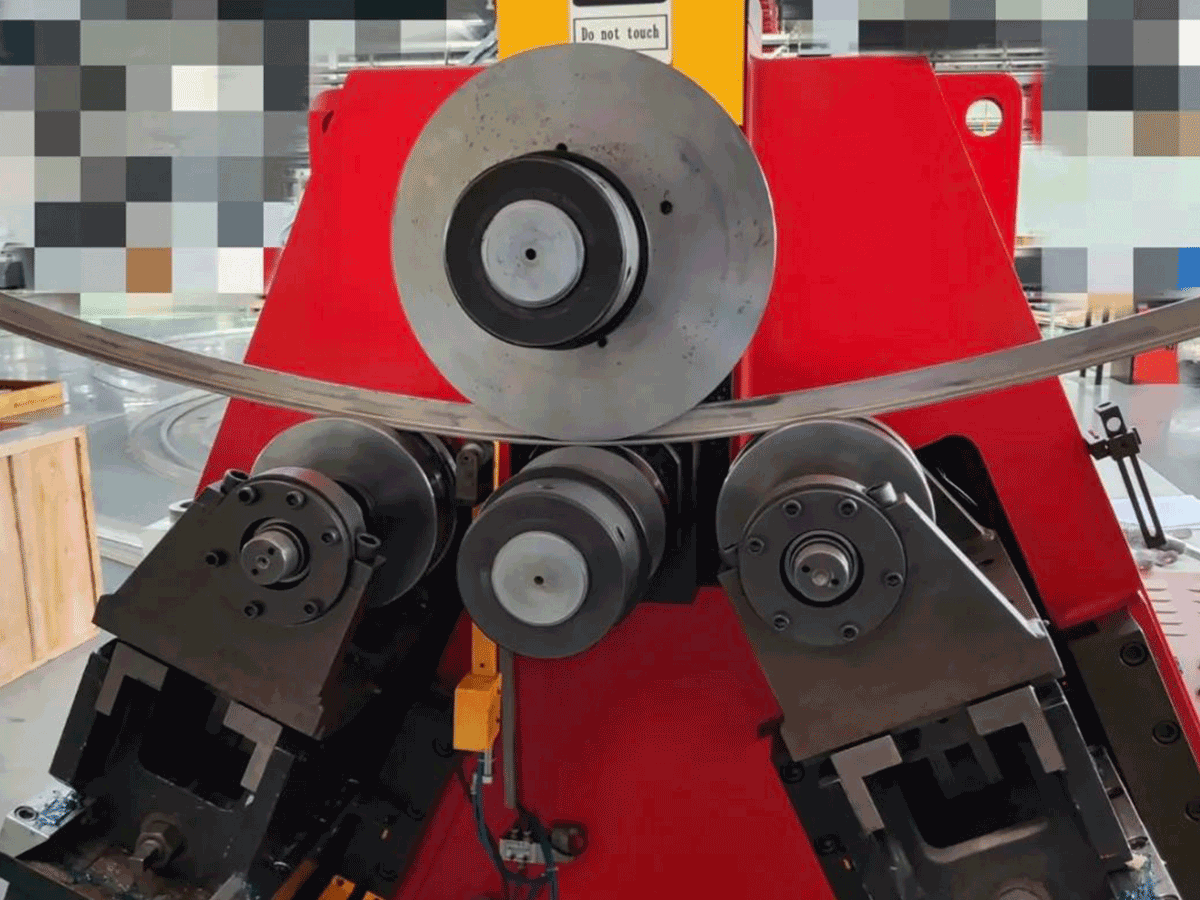

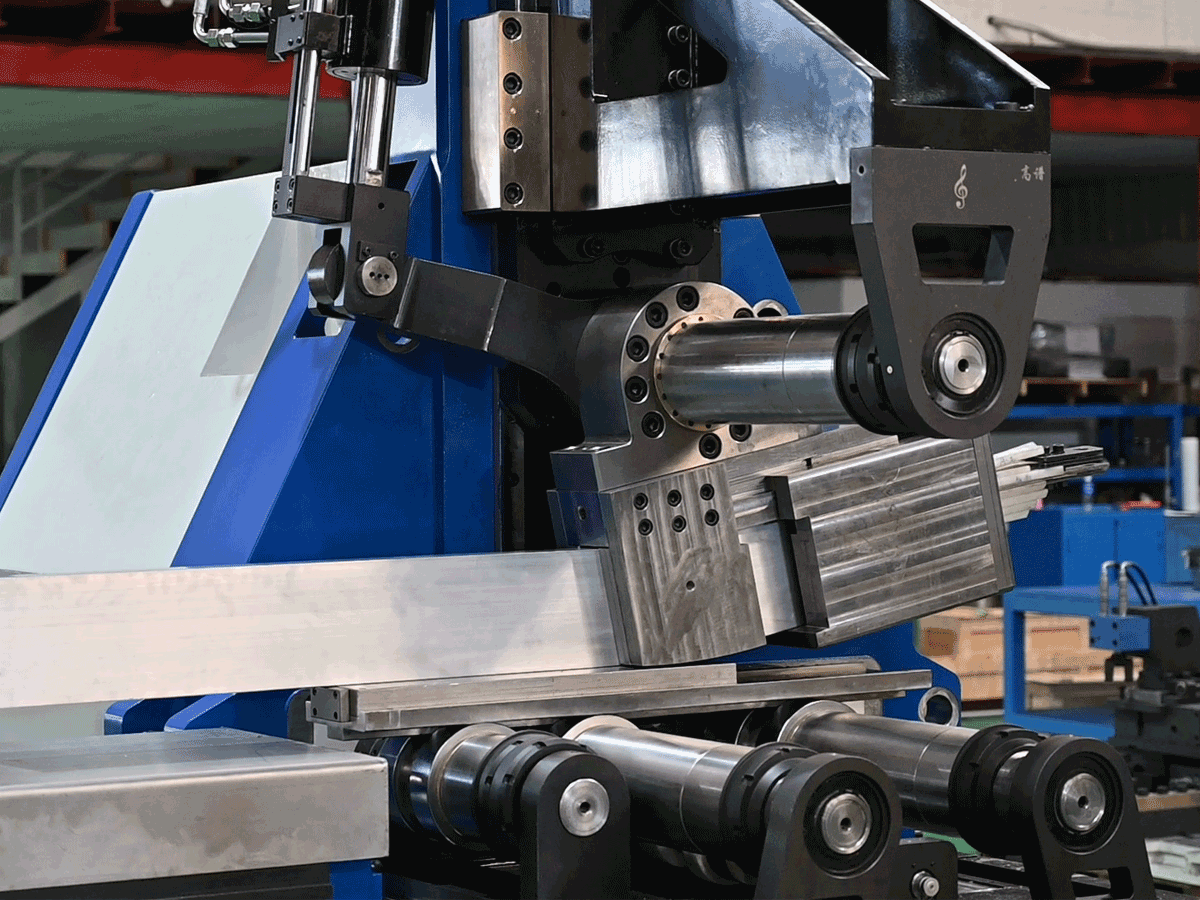

Roll bending is the blank in the roller under the action of bending moment gradually bending forming process, compared to pull bending forming, rolling more like a “master key”, its mold size is not limited by the length of the profile, a set of mold to adapt to different curvature of parts, and the equipment occupies a small area. In fact, roll forming has been widely used in many civilian industries, such as automobiles, construction, lighting manufacturing, subject to extremely high requirements for precision, and rarely used in the aerospace field.

According to statistics, after roll bending instead of stretch bending, production efficiency can be increased by 40%, mold cost reduced by 70%, and total cost reduced by 40%. Taking the development of a new model as an example, the bending die and jaws used only for the new right-angle profile frame cost about 3.48 million yuan, but if it is replaced by roll forming, only about 900,000 yuan is required to add 6 sets of rollers. And this saving of 2.58 million yuan is only a drop in the bucket in the total amount of “cost reduction” after rolling instead of bending.

The blade of the sword is sharpened, and the fragrance of plum blossoms comes from the bitter cold. Behind the excellent results of creating the “master key” of roll bending and forming and realizing the three efficiency increases of “quality improvement, cost reduction, and staff reduction” is the result of nearly one year of research and demonstration by the R&D team of the our workshop project and three consecutive weeks of overtime testing; It is the breakthrough and enterprising of “passing the difficult pass” and never giving up; It is also the best embodiment of their active innovation and self-innovation.

There is never an end point in the journey of innovation. In the future, the our workshop of Tianjin Rocket Company will further explore the rolling forming mechanism and deformation law of profile end frames, control the forming accuracy and consistency, and strive to realize the model application as soon as possible.

Article Source: https://mp.weixin.qq.com/s/C1k2clbBP9TvTW727cH9YA

Leave A Comment