what is Profile bending machine?Profile bending machine (also called section bending machine) is a machine that cold-bends a variety of metal profiles according to the principle of three-point circle. It can curl the profiles into round, arc, spiral and other workpieces.

Page Contents

Definitions

3-roll & 4-roll machines

Working principle

Bending method

RemarksDEFINITIONS

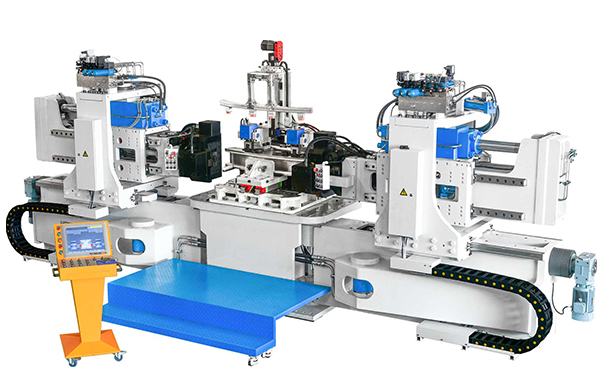

Profile bending machine of G Clef

Profile bending machine are the ideal machine for metal profile pre-bending and bending.

It is widely used in petroleum, chemical, shipbuilding, hydropower, metal structure,car and machinery manufacturing industries.

3-ROLL & 4-ROLL Profile bending MACHINES

Profile bending machines come in 3-roll or 4-roll models.

The 4-roll machine has one more pressure roller than the 3-roll machine, which can clamp the profile more under the upper roller and improve the bending accuracy (when the precision of the three-roll machines bending die is very high, the four-roll machines will also lose its unique Advantage), but it will make the operator’s operation more cumbersome, while reducing the bending ability of the same model.

Whilst four roll machines produce fast, accurate bends, three roll machines are ideal for fabricators working with a wide range of material types.

WORKING PRINCIPLE of Profile bending machine

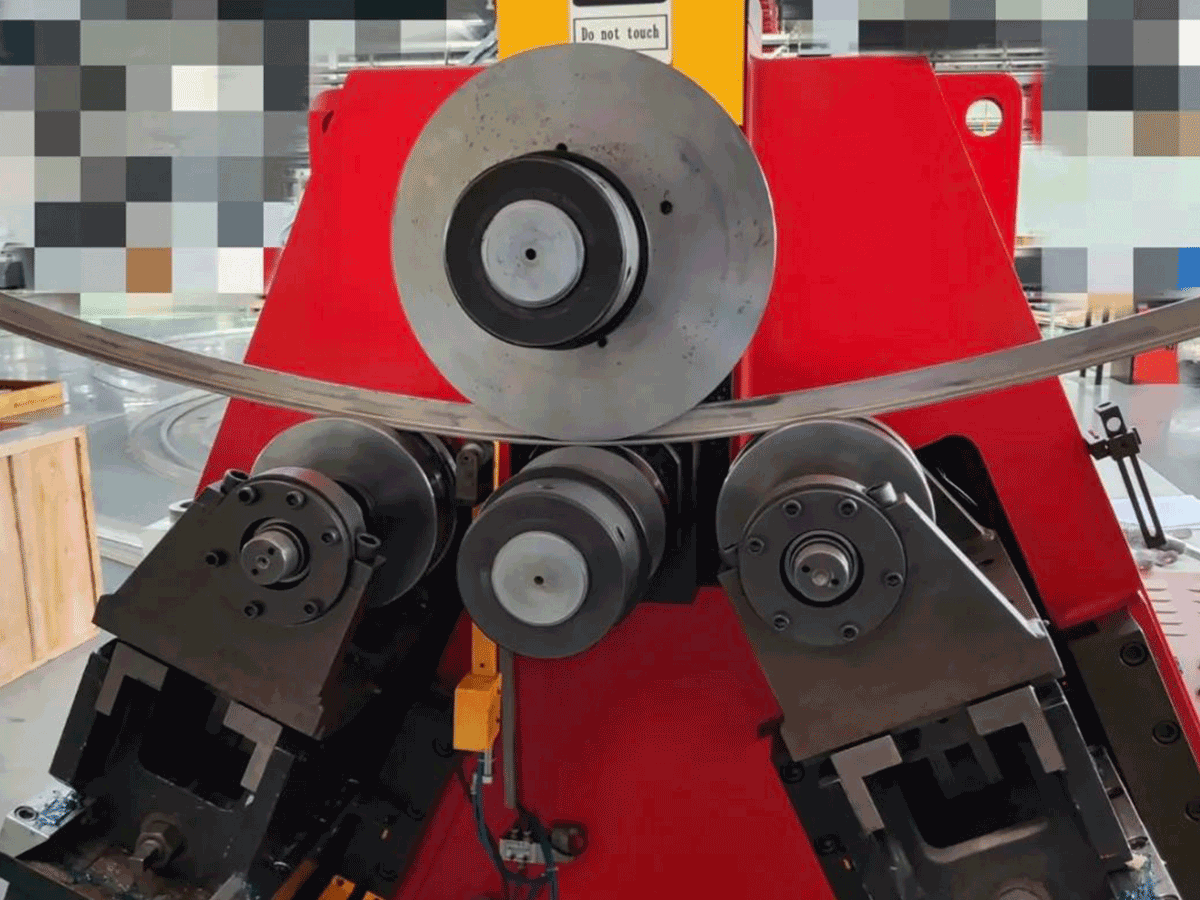

section bending working principle

The relative position change of the workpiece (through the up and down movement of the upper roller shaft or the lower and upper roller shaft) and the pressure generated during the rotation movement in the direction perpendicular to the deformation of the profile itself cause the profile to produce continuous plastic deformation (make the outer layer of the profile Deformation) The fiber stretches, the inner fiber shrinks to produce bending deformation, the middle fiber does not change), and the workpiece with a predetermined shape is obtained at room temperature (we call it cold bending).

BENDING METHOD

Symmetrical bending

Symmetrical bending: refers to the three rollers in a symmetrical shape (pyramid shape) during bending. The upper roller or the two lower rollers rotate in a symmetrical relative position at the center to apply pressure to the profile to produce plastic deformation

Disadvantages: It is not possible to pre-bend the profile. There are larger straight edges at the end of the workpiece after bending, which causes waste.

asymmetrical bending

Asymmetrical bending: refers to the asymmetrical shape of the three rollers during bending. The upper roller and the two lower rollers move vertically at asymmetrical central positions, and the upper roller or the two lower rollers rotate to exert pressure on the profile. Produce plastic deformation. The end of the profile can be pre-bent.

REMARKS

Various metals include carbon steel, stainless steel, aluminum, copper, etc.

Profiles include angle, flat bar, round bar, square bar, round pipe, square tube, channel, beam, tee, etc.

IMPORTANT LINK

List of our products:profile bending machine of G Clef

Must know section bending information:Profile bending machine videos on YouTube

Leave A Comment