-

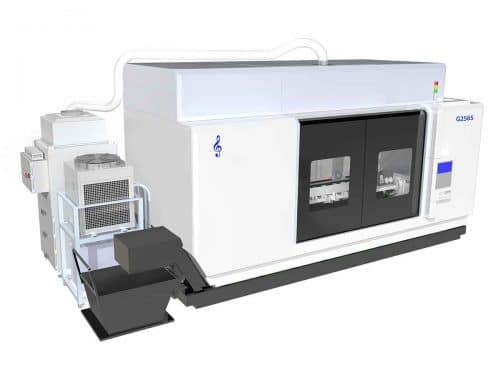

A New Era in Profile Processing!Not a replacement, but an extension of existing CNC technologyExclusively designed for profiles, delivering professional-gradeprecision in CNC machine. 5-axis composite machining center integratinglaser cutting, driling and millingEquipped with: *A-axis rotary fixture *B-axis ±90° tilting high-speed electric spindle Primary Applications: Automotive bumper beams, crash boxes, sill beams, railway, and aerospace

A New Era in Profile Processing!Not a replacement, but an extension of existing CNC technologyExclusively designed for profiles, delivering professional-gradeprecision in CNC machine. 5-axis composite machining center integratinglaser cutting, driling and millingEquipped with: *A-axis rotary fixture *B-axis ±90° tilting high-speed electric spindle Primary Applications: Automotive bumper beams, crash boxes, sill beams, railway, and aerospace -

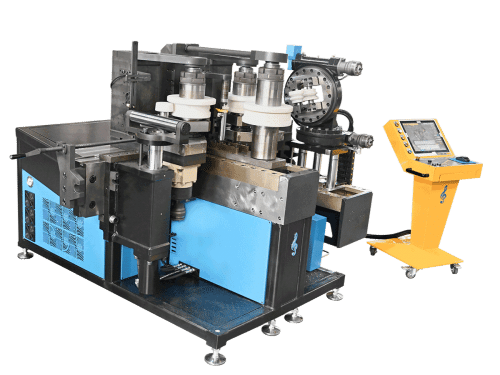

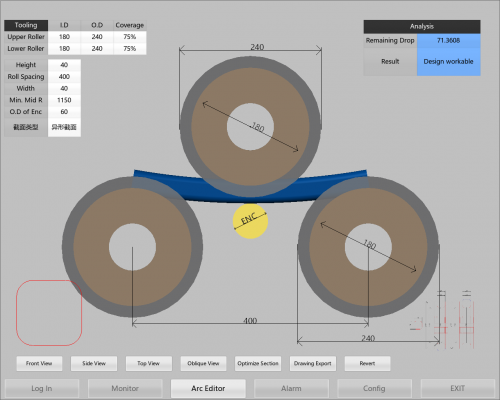

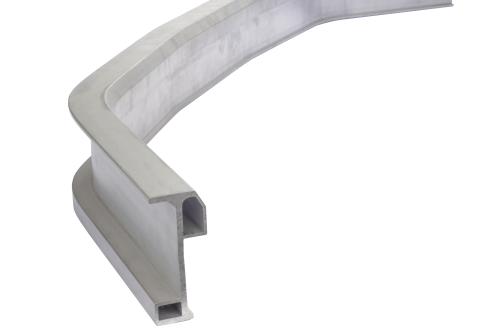

G-Clef vertical CNC roll bending machine A20T is widely used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, gym equipment and other industries. 2D /3D bending is optional. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. Profile max cross-section area: 100*100*3mm. Min. bending radius: section height* 5-8.

G-Clef vertical CNC roll bending machine A20T is widely used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, gym equipment and other industries. 2D /3D bending is optional. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. Profile max cross-section area: 100*100*3mm. Min. bending radius: section height* 5-8. -

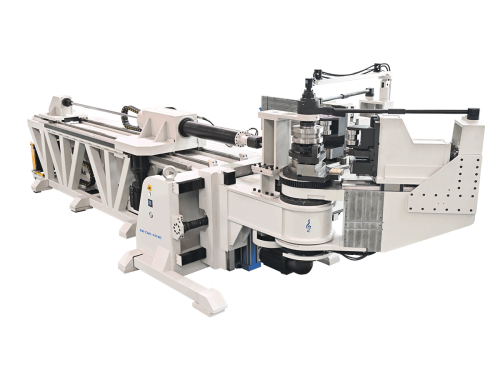

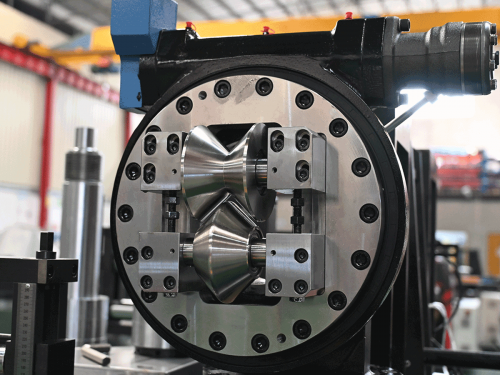

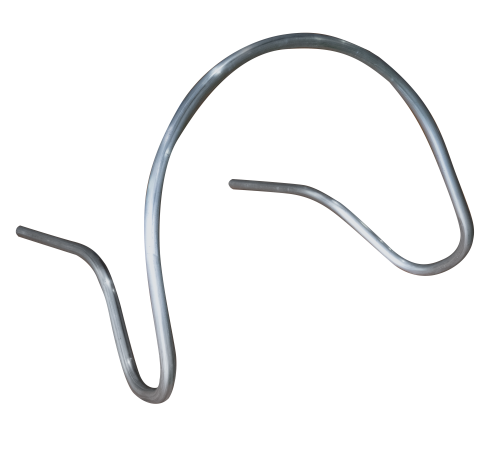

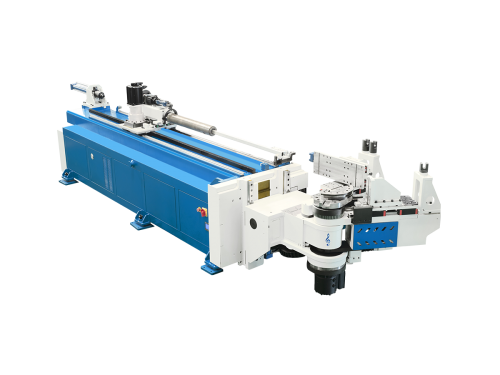

Equipped with a CNC system, G Clef tube bending machine has the bending capabilities of multi-radius, multi-angle, and multi-direction. Adopting original eccentric bending technology, it can realize small radius bending. Moreover, there is no need of manual correction after bending. It can be adapted to a wide range of machines (robot grippers, drilling devices, etc.), and realize automated production.

Equipped with a CNC system, G Clef tube bending machine has the bending capabilities of multi-radius, multi-angle, and multi-direction. Adopting original eccentric bending technology, it can realize small radius bending. Moreover, there is no need of manual correction after bending. It can be adapted to a wide range of machines (robot grippers, drilling devices, etc.), and realize automated production. -

This device is capable of scanning objects for inspection of bending quality. Comparing the 3D data with the original CAD model for full-size inspection and analyzing the difference between the final product and the design, it can easily, quickly and accurately detect errors in complex shapes. It is an excellent helper in improving product quality.

This device is capable of scanning objects for inspection of bending quality. Comparing the 3D data with the original CAD model for full-size inspection and analyzing the difference between the final product and the design, it can easily, quickly and accurately detect errors in complex shapes. It is an excellent helper in improving product quality. -

G-Clef vertical CNC roll bending machine A30T is widely used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, gym equipment and other industries. 2D /3D bending is optional. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. Profile max cross-section area: 100*100*3mm. Min. bending radius: section height* 5-8.

G-Clef vertical CNC roll bending machine A30T is widely used in new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, gym equipment and other industries. 2D /3D bending is optional. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. Profile max cross-section area: 100*100*3mm. Min. bending radius: section height* 5-8. -

Vertical roll bending machine A12T can bend multi-radius arcs, ellipses, parabolas and other curvatures. 2D or 3D bending function is available. The 4th roller can be customized based on your needs. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. As our mature product, the sample-making period and lead time are short to satisfy your urgent needs. Profile max cross-section area: 60*60*3mm. Min. bending radius: section height* 5-8.

Vertical roll bending machine A12T can bend multi-radius arcs, ellipses, parabolas and other curvatures. 2D or 3D bending function is available. The 4th roller can be customized based on your needs. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. As our mature product, the sample-making period and lead time are short to satisfy your urgent needs. Profile max cross-section area: 60*60*3mm. Min. bending radius: section height* 5-8. -

Vertical roll bending machine A45T can bend multi-radius arcs, ellipses, parabolas and other curvatures. 2D or 3D bending function is available. The 4th roller can be customized based on your needs. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. As our mature product, the sample-making period and lead time are short to satisfy your urgent needs. Profile max cross-section area: 220*120*3mm. Min. bending radius: section height* 5-8.

Vertical roll bending machine A45T can bend multi-radius arcs, ellipses, parabolas and other curvatures. 2D or 3D bending function is available. The 4th roller can be customized based on your needs. With CNC control system and servo-drive technology, it can achieve high-quality bending and help you get rid of the dependence of operating experience, reducing your labor cost. As our mature product, the sample-making period and lead time are short to satisfy your urgent needs. Profile max cross-section area: 220*120*3mm. Min. bending radius: section height* 5-8.