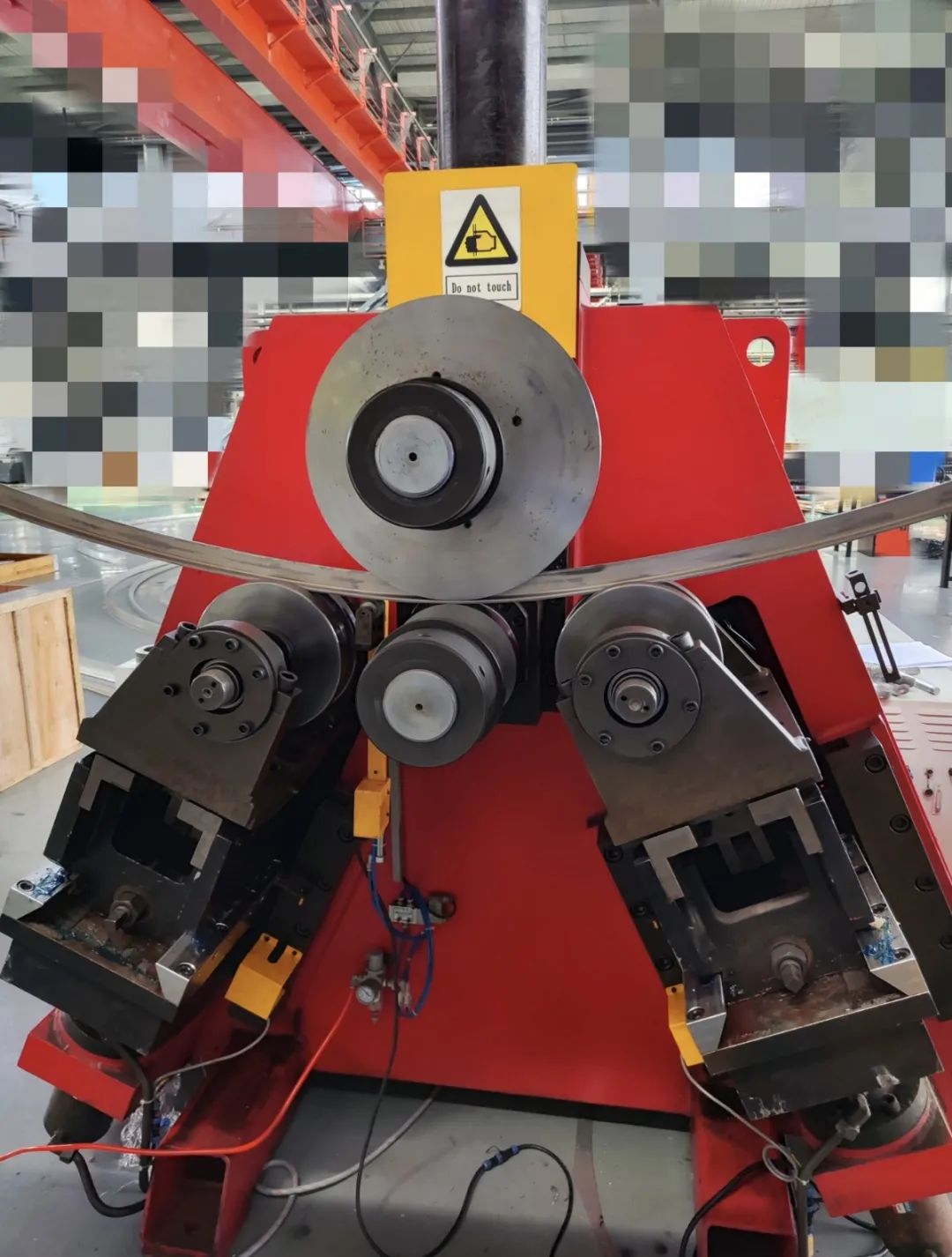

Roll bending machine is used to continuously process straight materials. All kinds of arc-shaped parts, also suitable for the roll bending machine to process. And the revolving door has to let the flow of people continue to pass, at the same time with the function of continuous opening and closing, gathering the advantages of wind resistance, energy saving, isolation of air flow and so on gathered all kinds of door body, is the finishing point of modern buildings.

The bending machine produces the curved parts that the revolving door needs, so they begin a long story.

The development of revolving doors dates back to the 1920s in Italy, when two wing doors were designed to swing open in both directions. Later, a Swedish revolving door manufacturer introduced a new two-wing door. They added electric motors and booths to the original design, and there were three-wing doors and four-wing doors. By the 1940s, rotation speed controls were added to the revolving door to keep the speed of the door under control as required. With the development of industrialization, automation, all kinds of automatic door revolving door, with card identification safety performance revolving door, with a variety of safety protection sensors automatic door and many special purpose revolving door have joined the original manual four-wing door series, so that its continuous development, to have an automatic revolving door. The development of automatic doors is not only due to its anti noise and dustproof performance, a very important point is its energy-saving characteristics.

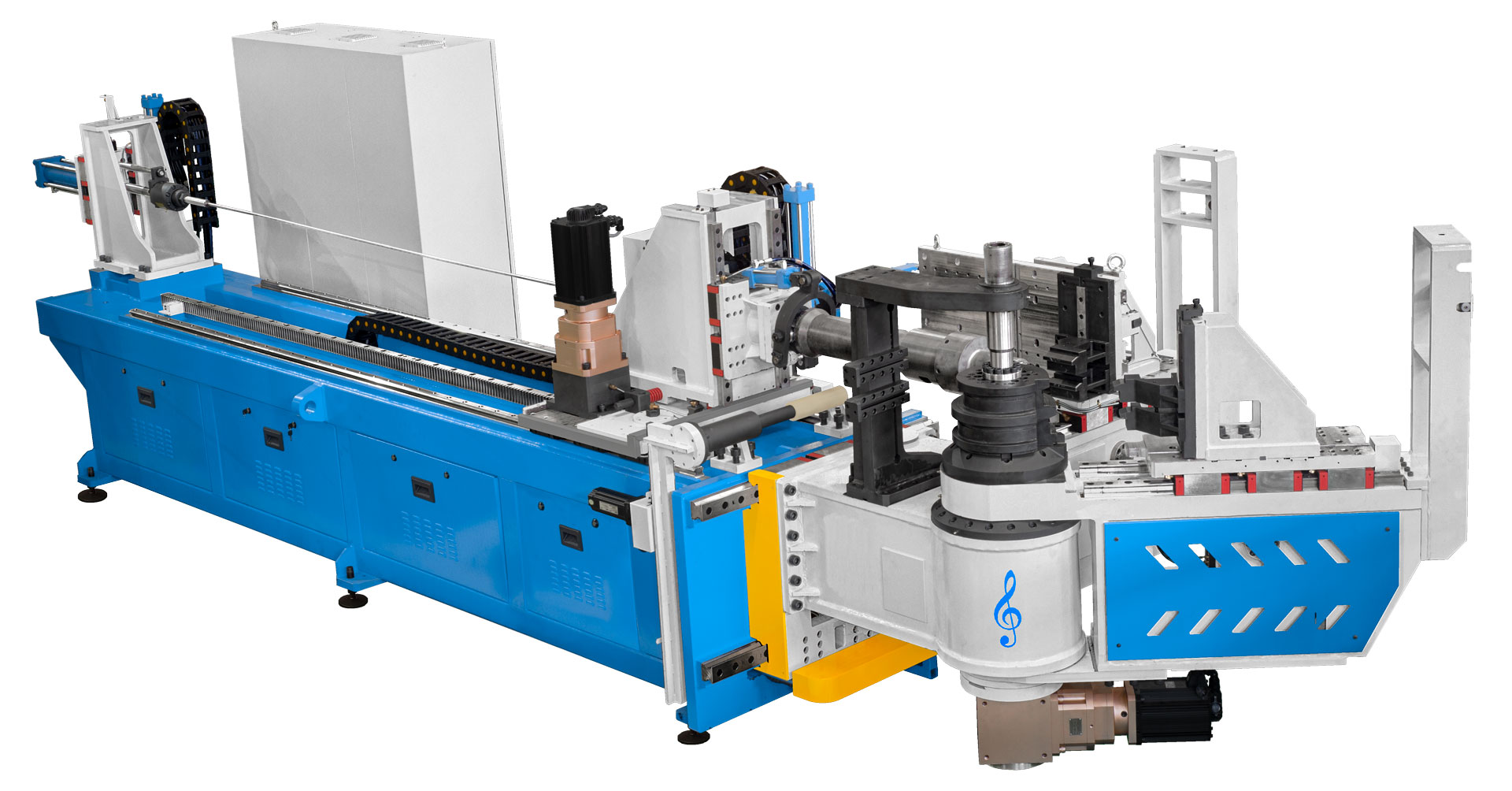

The development of the roll mill came at the end of the 18th century, when British industrialist John Wilkinson invented the reversible mill. Mid-19th century: The first “plate bending brake” is manufactured. From the early to mid-20th century, bending systems became more and more electrified. The first simple control system was developed to control clamping, bending and cutting functions. From then on, the rolling machine was almost self-controlled. In the early 1990s, the first rolling machine with CNC and monitoring system was built. Measurement systems are becoming more accurate and faster. In the late 1990s, graphics control systems were added to these systems, followed by touch screens that could be operated directly with a finger. At the turn of the century, automatic double rolling machine ushered in the majestic development.

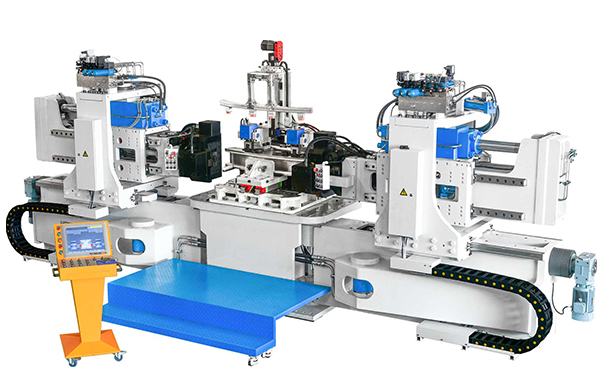

G Clef company’s bending machine becomes more accurate and faster. The bending process will be further automated and, more importantly, it will be better interconnected with higher-order software components — for example, CAD drawings can be imported for automated machining.

G Clef company’s bending machine flexible, compact, precise characteristics, so that the design and processing of the revolving door also profit from — so we walk in the metropolis, can be seen everywhere spacious, luxurious revolving door……

Leave A Comment