Roll bending machine is more and more widely used in modern industry, including for the manufacture of escalators. A primer on escalators:

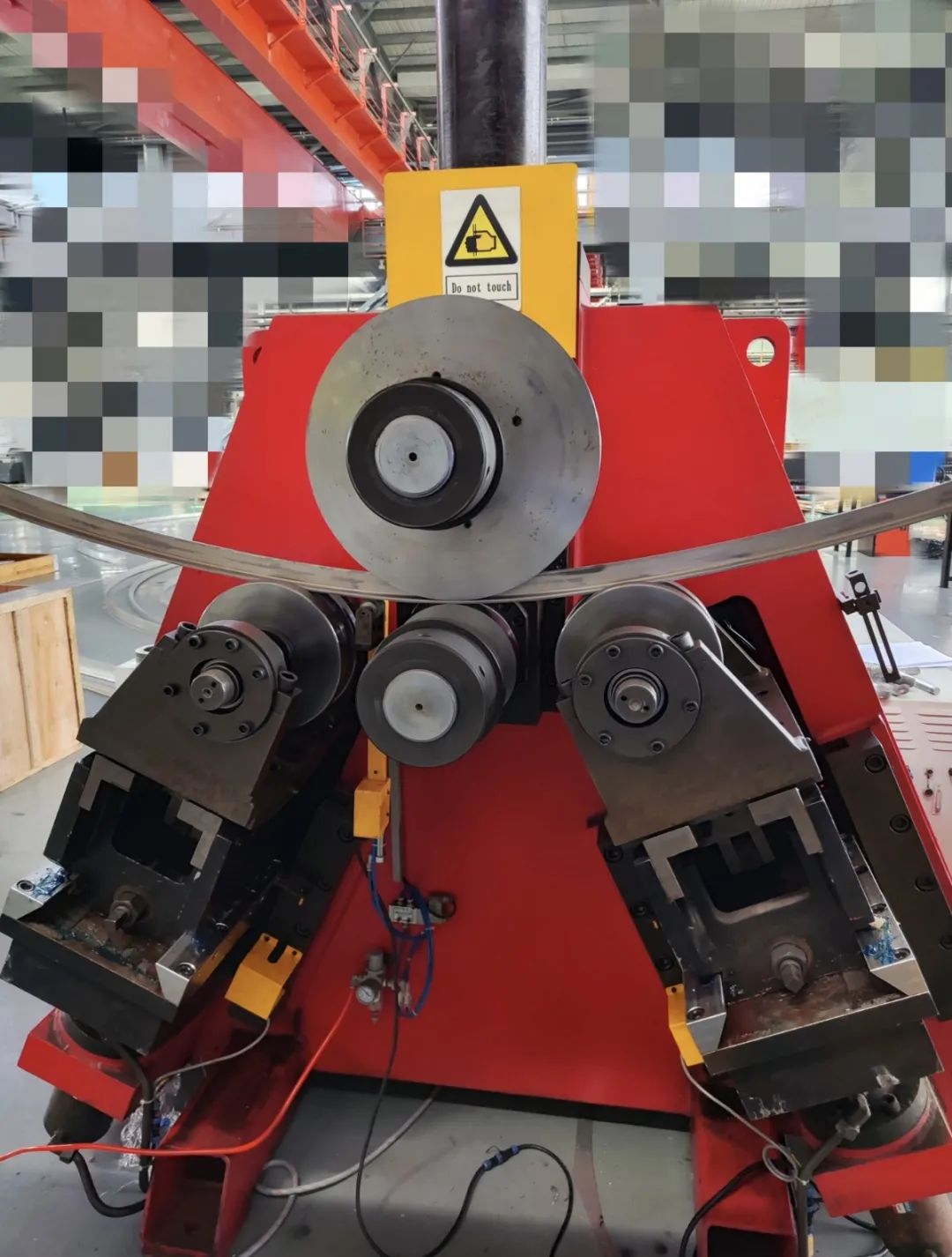

Compared with the vertical elevator, the escalator is an open elevator, which can take a steady flow of passengers at the same time, but also to solve the problem of air circulation, so it is widely installed in large shopping malls, stations, airports and other places with a special flow of people. Anyone who has ever ridden an escalator is familiar with it, especially its two curved handrails, which can be bent with a roll bender!

Why are rolling machines used more and more? It takes a lot of energy to heat the metal into a liquid that is then poured into the mold, and it needs to be cooled to form. Especially for some small pieces, thin pieces of parts, the accuracy of the mold requirements are higher, the process is more complicated, will waste a lot of resources and time.

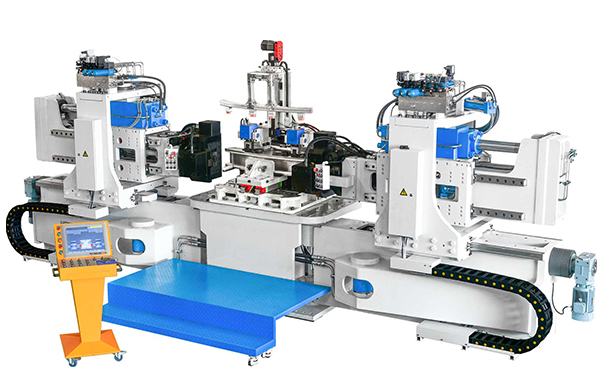

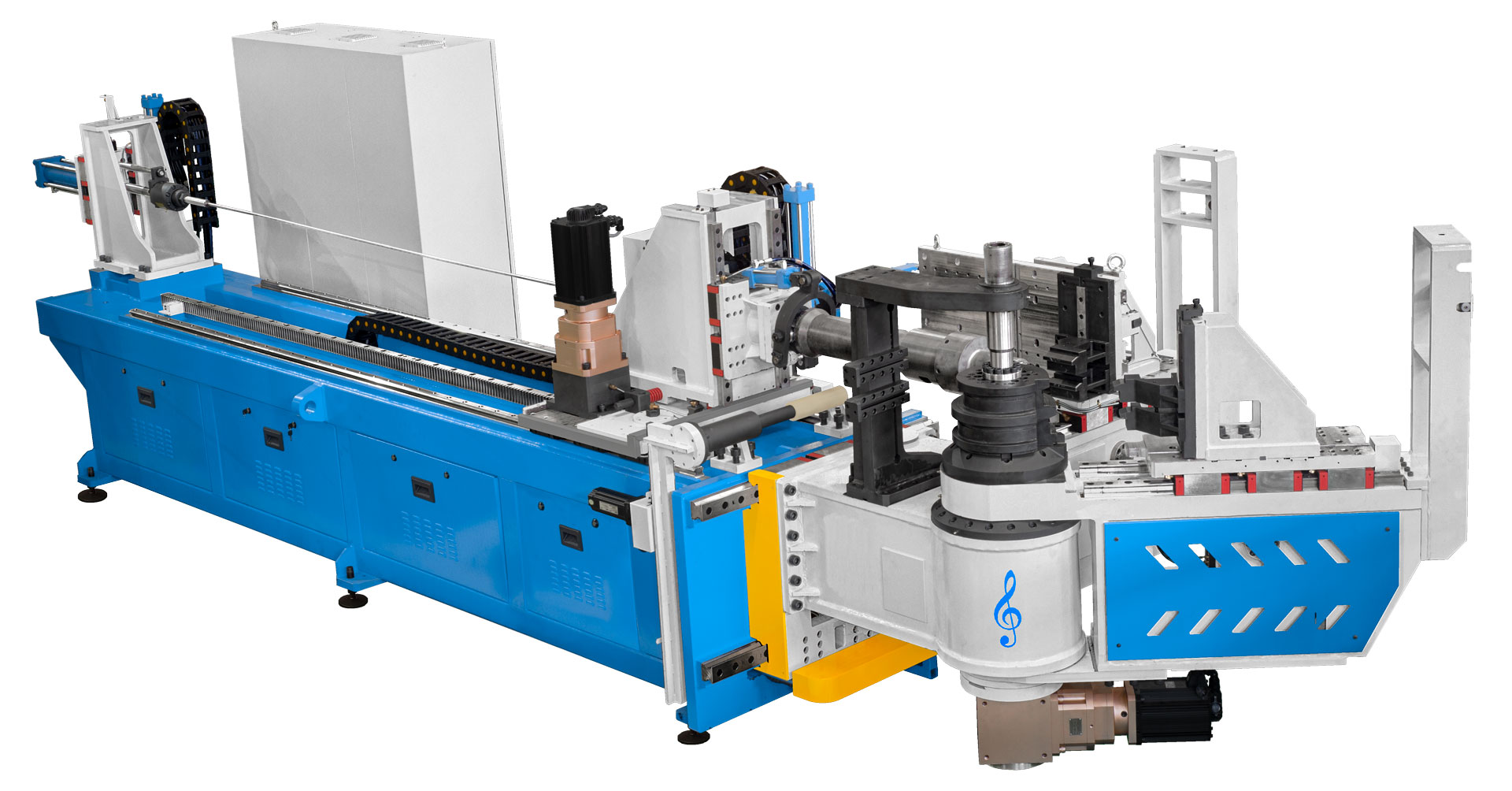

G Clef CNC rolling Bender intelligent analysis of metal material characteristics, but also can import design drawings such as CAD drawings, can be automatically processed, or divided into several rolling molding – straight material bending into the design appearance, greatly improve production efficiency. This is why more and more elevator manufacturers are starting to use rolling mechanisms for escalator parts.

Leave A Comment