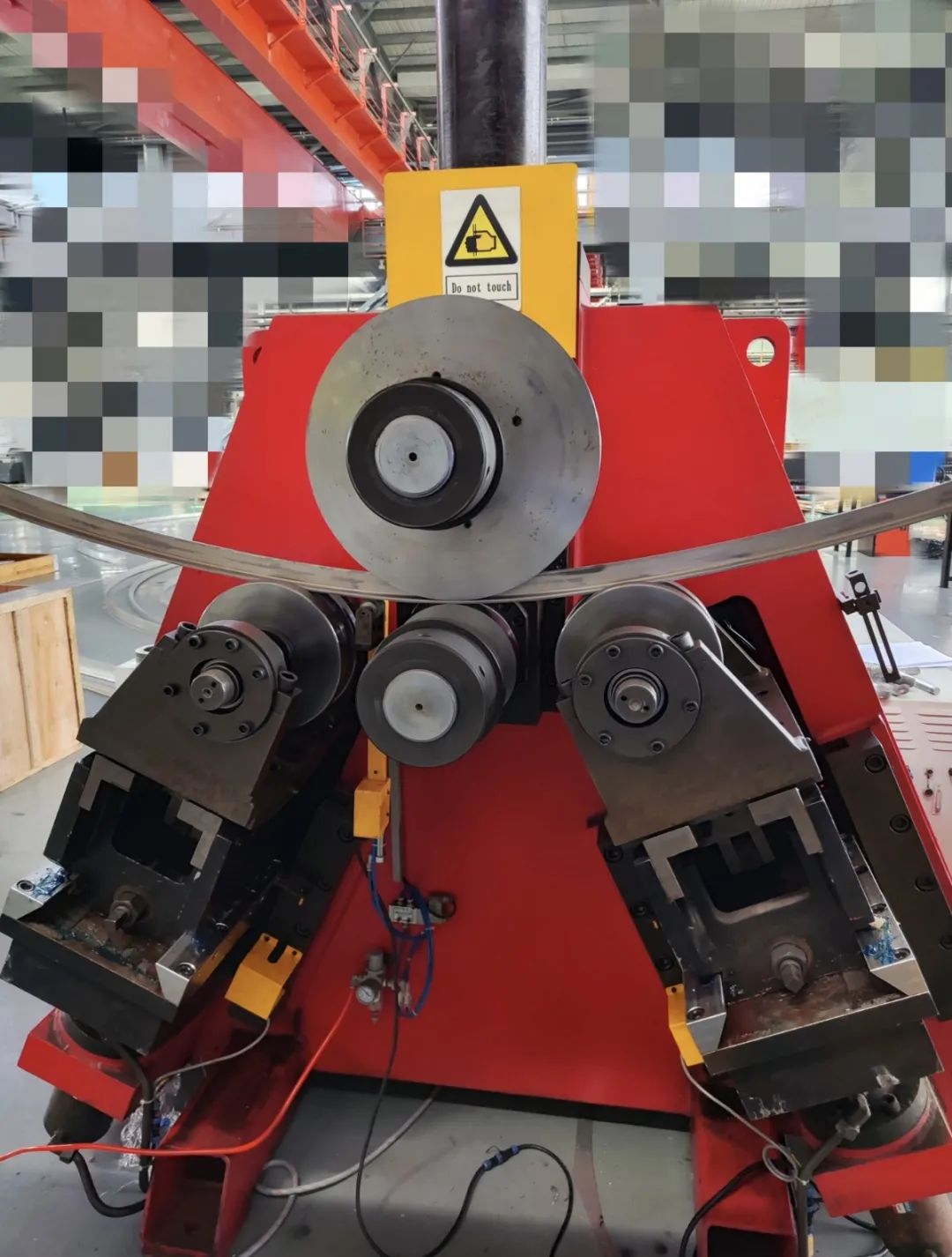

The bending characteristic of the roll bending machine is that it can continuously bend the straight material into the shape of an arc or a curvature arc. The shape of the aircraft needs to conform to the aerodynamic shape, just is also the arc or curvature arc is the main, so the roller bender is more used in aircraft manufacturing. Such as:

The bending machine is used to bend the aircraft frame, the bending machine to strengthen the rafters of the aircraft and a large number of aircraft variable curvature arc parts and so on.

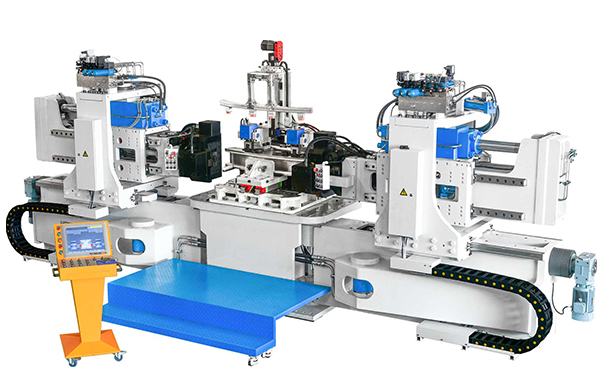

G Clef CNC roll bending machine with its high precision, flexible, compact characteristics, as well as the accumulation of years of rich processing experience, a large number of supporting optional accessories, perfect to solve the traditional rolling machine low production efficiency, easy to appear material section deformation, concave and convex and other problems. Therefore, the G Clef bending function processing many special-shaped section, such as U, T, Z and so on, can be used to bend bending machine processing.

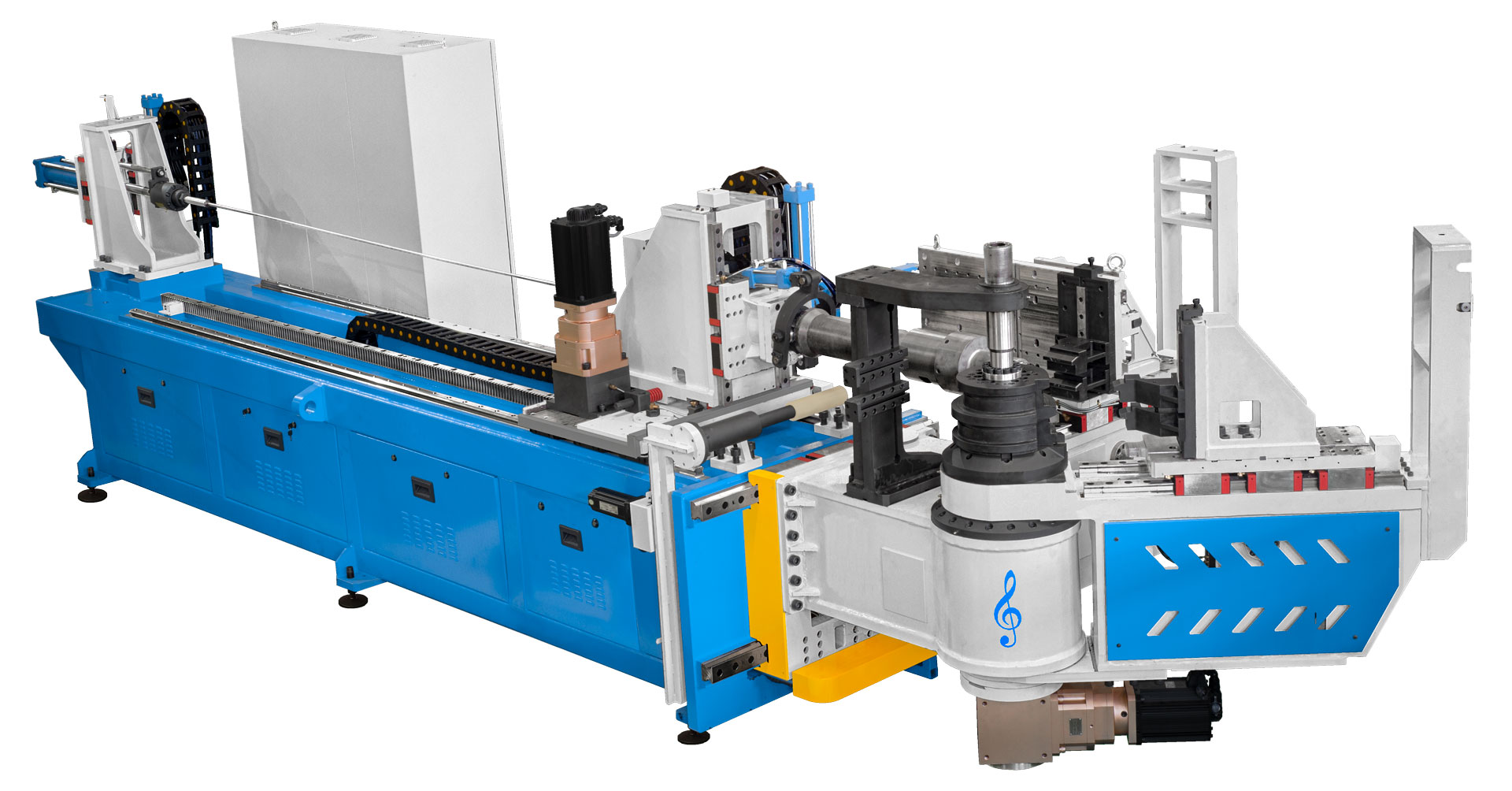

The numerical control system equipped with the G Clef bending machine has the function of analyzing the material characteristics, which completely solves the dependence on the experience of the operators in the traditional bending forming process. Therefore, the use of the rolling machine becomes easy to understand.

Roll bending machine with numerical control system, at the same time has a strong expansion, can import CAD drawings, automatic generation of processing procedures, has the potential of automatic production – G Clef bending technology to roll bending machine processing more easy, simple.

The above is the use of roll bending machine in aircraft production, but the roll bending machine can not only assist in the manufacture of aircraft, but also can bend a variety of curvature arc parts…

Leave A Comment