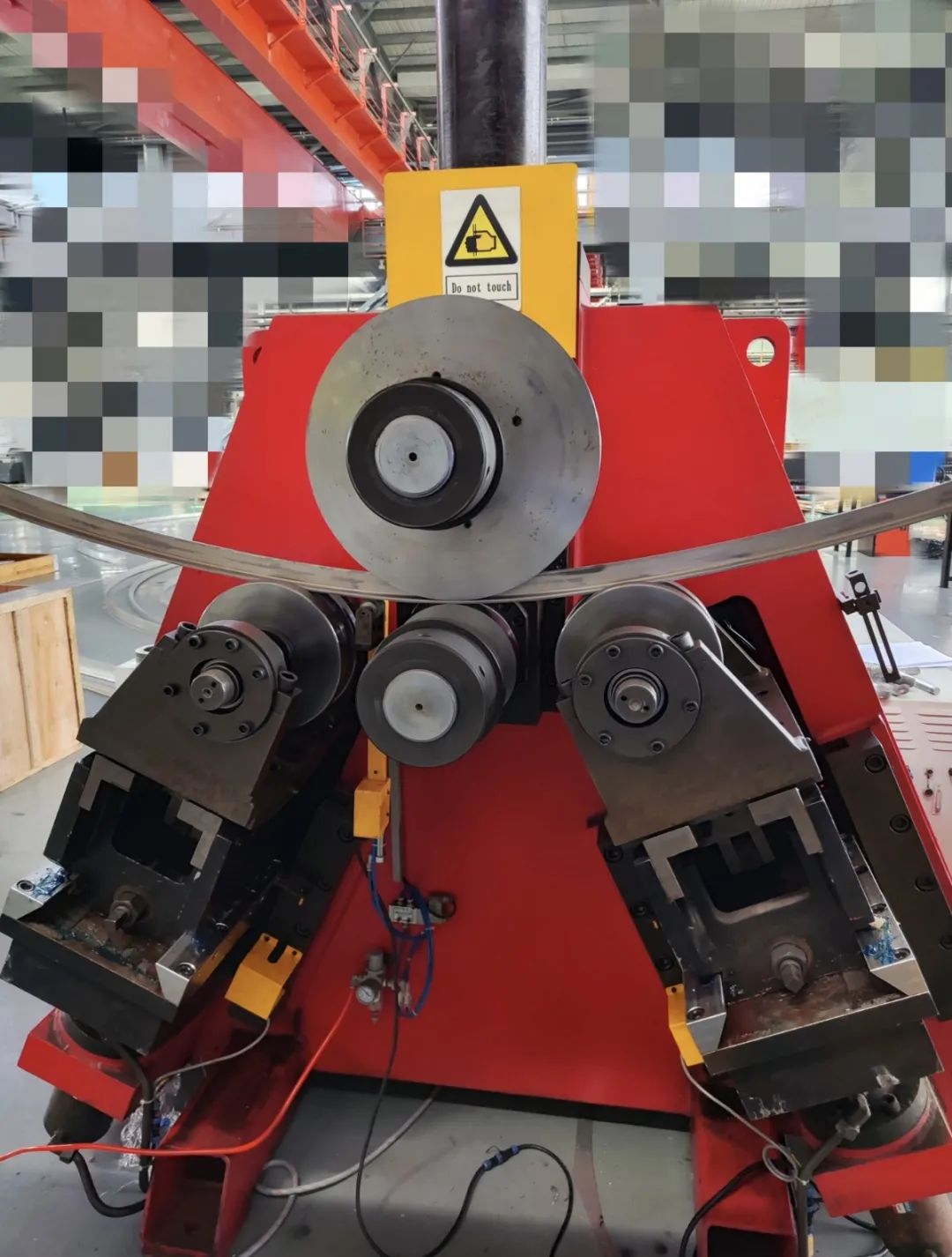

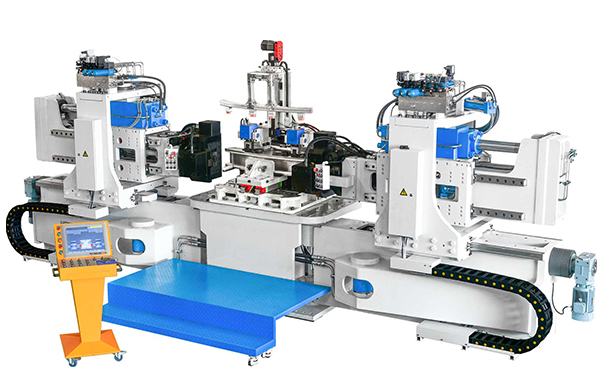

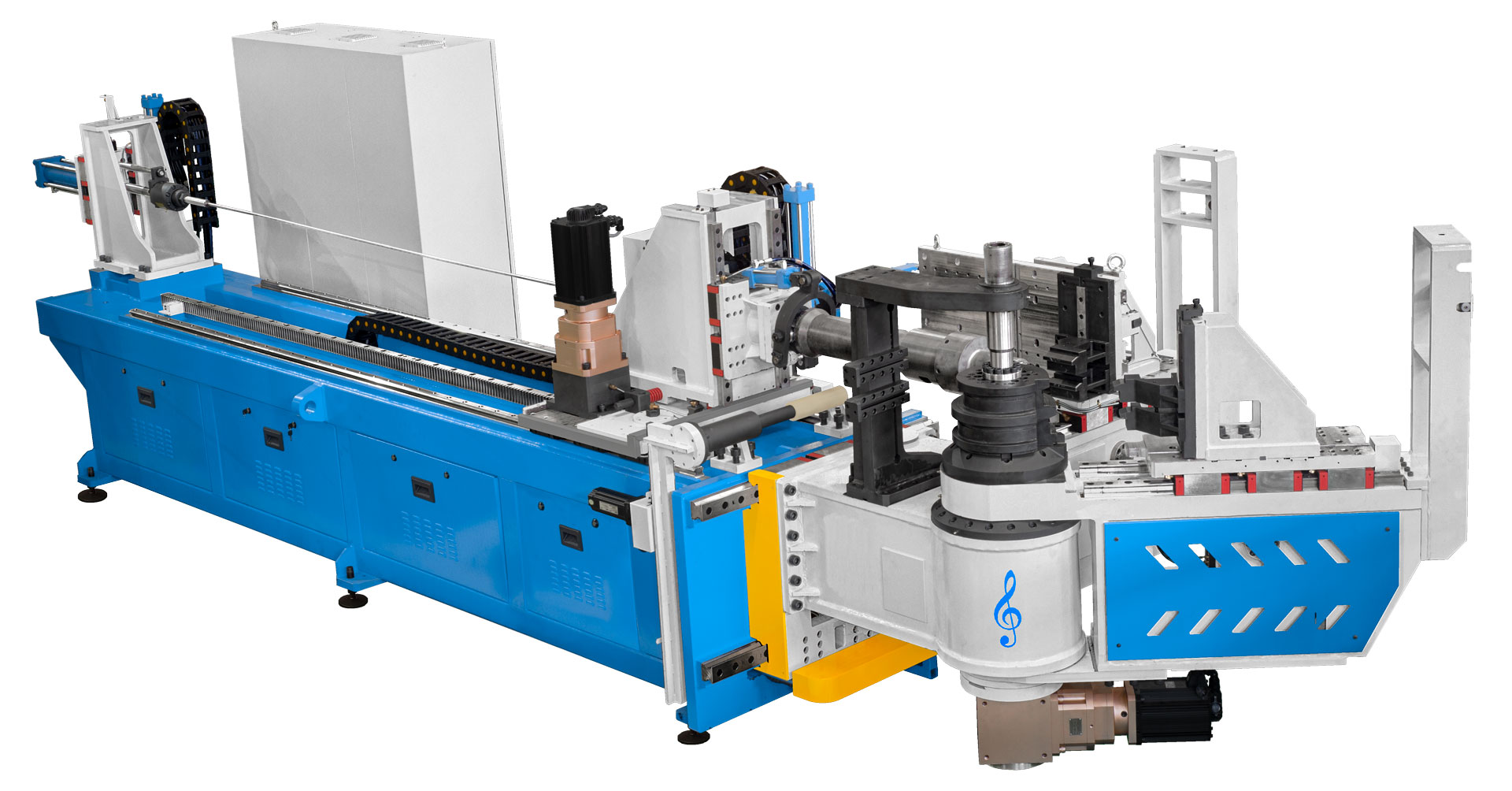

G Clef’s CNC rolling machine has a variety of models, processing range and processing ability is outstanding, suitable for the bending forming a number of bending processing industry, the processing and manufacturing of new energy vehicles is no exception.

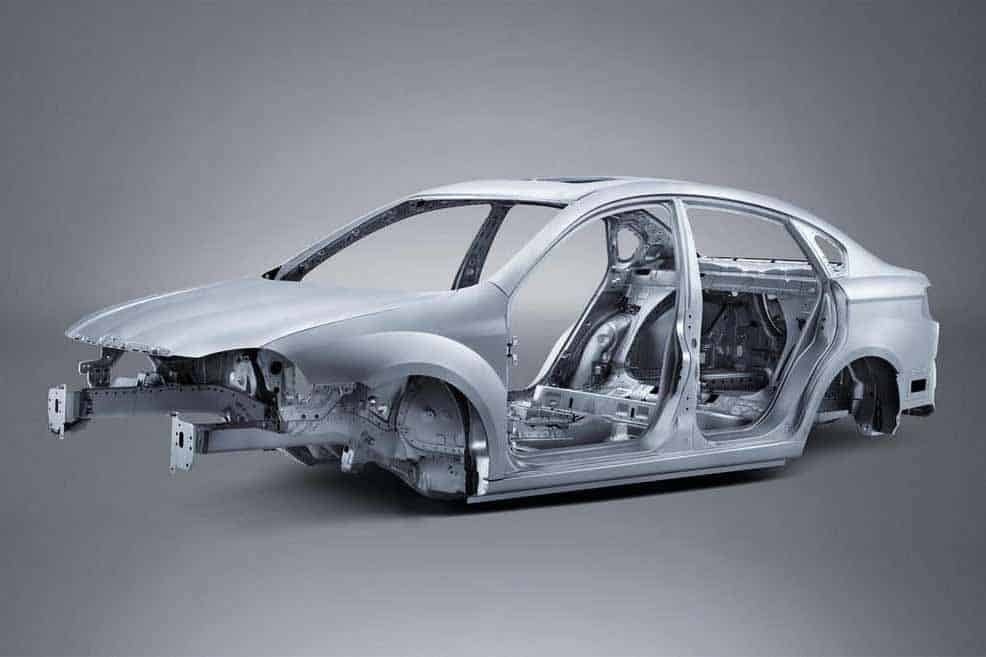

New energy vehicles abandon components such as car engines and need to adopt different body structures from traditional cars. This brings new challenges to the design and manufacture of new energy vehicles. At this time, the rolling machine developed by companies that continue to focus on the field of cold forming stood out, providing new ideas and solutions for new energy vehicle manufacturers. So what are the advantages of G Clef rolling machine?

The bending pressure of the roll bending machine developed by G Clef can reach 120 tons, and it can bend and shape most of the workpiece of new energy vehicles. At the same time, the use of NC system, hydraulic technology, can import CAD drawings automatic calculation, multiple bending, and the positioning accuracy of the crankshaft reached 0.01 mm! Such intelligent and not rely on skilled workers, simple and easy to operate without losing high accuracy of the bending equipment, it has become the right-hand man of the bending of the automobile frame!

Leave A Comment