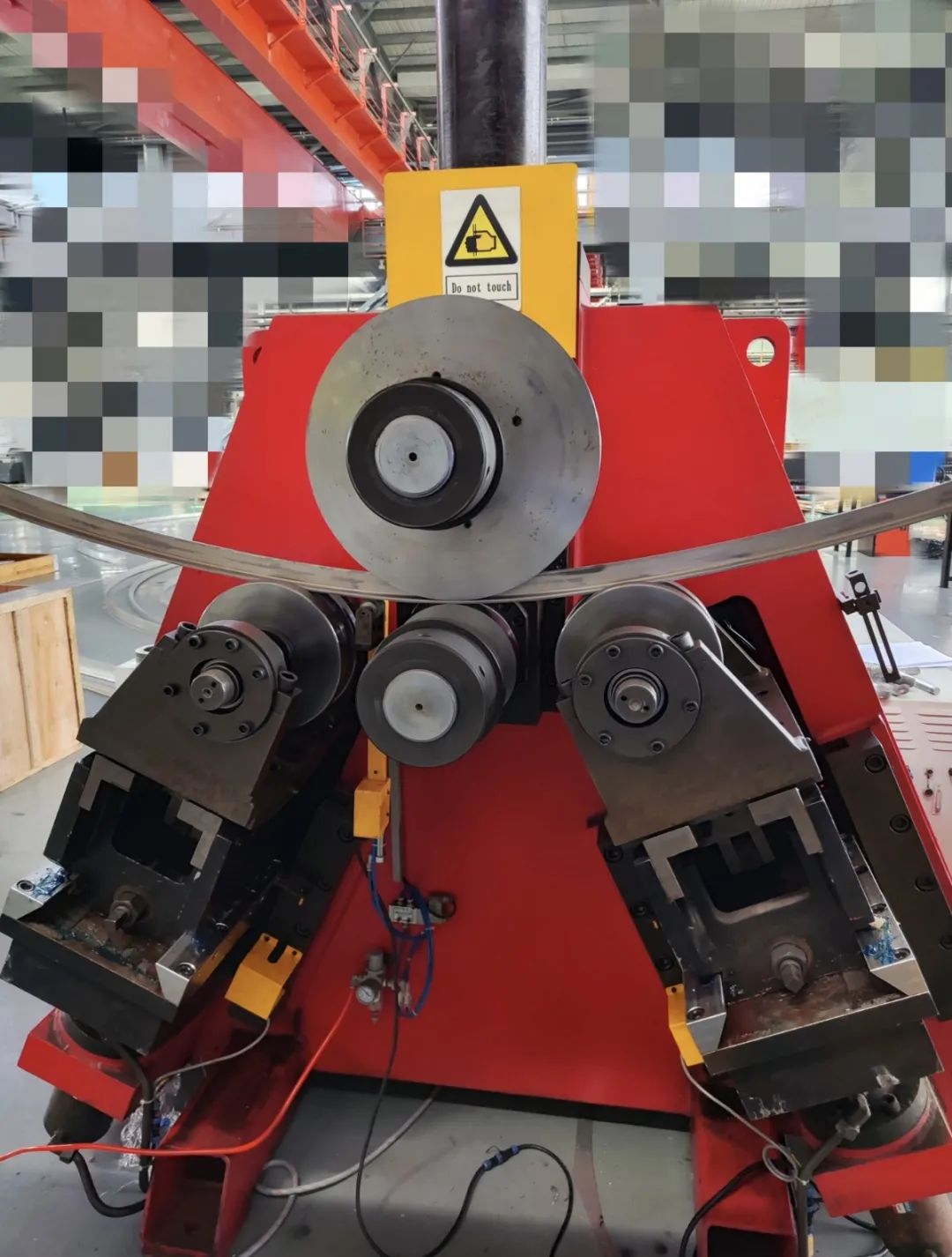

The CNC steel bending machine is a mechanically controlled bending machine to replace the artificial bending machine. It mainly processes the bar steel bar and can bend the national standard steel bar within 50mm. The equipment can process multiple steel bars at one time, and has the advantages of processing shape standard and large processing capacity.

It can replace 20-30 people. The equipment can be used with the CNC steel cutting production line, or it can work alone. It can automatically and high-bending the steel bars for construction, and can process special super-strong steel bars such as China Railway and Nuclear Power Project.

The device has the ability to simultaneously perform multi-directional bending in one working unit, and the two bending main machines work at the same time, which greatly improves the efficiency, can carry 5 tons of raw materials, and greatly reduces the labor intensity. Widely used in construction and other fields. One bending machine is fixed, and the other bending machine can be moved automatically.

The operation mode is divided into manual and automatic modes. The steel conveying table is composed of multiple power rollers, which complete the automatic conveying and storage of steel bars, and the conveying rollers are high. The quality rubber surface reduces noise and improves efficiency. The lift mechanism is pneumatically controlled to automatically position the steel bars onto the double-bending head and transfer the bent steel bars to the storage bin.

The multi-stage storage bin can store the finished finished steel bar. The convenient and fast control system adopts the imported C: it can set continuous work tasks, one cycle can process multiple angles, and has the task storage function. The bending motor is controlled by an imported frequency converter, the bending speed can be adjusted, and the accuracy of the bending angle can be controlled by an encoder.

Leave A Comment